Introduction

The manufacturing sector is undergoing its most radical transformation since the Industrial Revolution, driven by advanced robotics and automation technologies. From automotive plants to electronics assembly lines, intelligent machines are reshaping production processes with unprecedented precision, efficiency, and flexibility. This in-depth exploration examines how robotics is fundamentally altering manufacturing landscapes, the key technologies enabling this shift, implementation challenges, and what the future holds for human-machine collaboration in industrial settings.

A. The Robotics Revolution in Modern Manufacturing

1. Evolution of Industrial Robotics

- 1961: First industrial robot (Unimate) installed at GM plant

- 1980s: Introduction of SCARA robots for precision assembly

- 2000s: Collaborative robots (cobots) enter the market

- Present: AI-powered autonomous manufacturing systems

2. Key Benefits Driving Adoption

- Precision Engineering: Micron-level accuracy for complex components

- 24/7 Productivity: Continuous operation without fatigue

- Quality Consistency: Elimination of human error variations

- Hazard Mitigation: Handling dangerous materials and processes

3. Current Market Landscape

- Global industrial robotics market valued at $16.78 billion (2022)

- Automotive industry accounts for 30% of robotic applications

- Electronics manufacturing seeing fastest growth at 18% CAGR

B. Cutting-Edge Robotics Technologies Reshaping Factories

1. Collaborative Robots (Cobots)

- Force-limited designs for safe human interaction

- Quick deployment with minimal programming

- Applications in small-batch production and quality inspection

2. Mobile Autonomous Robots (AMRs)

- Smart navigation using LiDAR and computer vision

- Just-in-time material delivery systems

- Warehouse inventory management solutions

3. AI-Enhanced Robotic Systems

- Machine vision for defect detection

- Predictive maintenance capabilities

- Adaptive process optimization

4. Additive Manufacturing Robots

- Large-scale 3D printing systems

- Multi-material deposition capabilities

- On-demand production of complex geometries

5. Humanoid Factory Robots

- Dexterous manipulation like human workers

- Tesla’s Optimus and other emerging prototypes

- Potential for complete production line flexibility

C. Industry-Specific Transformations

1. Automotive Manufacturing

- Robotic welding with 0.1mm precision

- Autonomous guided vehicle (AGV) assembly lines

- Paint shop automation with consistent quality

2. Electronics Production

- Micro-scale component placement robots

- Automated optical inspection (AOI) systems

- Cleanroom-compatible robotic handlers

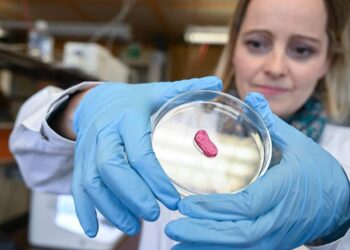

3. Pharmaceutical Industry

- Sterile packaging automation

- Laboratory automation for drug discovery

- Precision dispensing robots

4. Food and Beverage

- Sanitary robotic packaging lines

- AI-powered quality sorting

- Automated palletizing systems

D. Implementation Challenges and Solutions

1. Workforce Transition

- Challenge: Job displacement concerns

- Solution: Reskilling programs for robotic maintenance and programming

2. System Integration

- Challenge: Legacy equipment compatibility

- Solution: Modular robotic systems with adapters

3. Cybersecurity Risks

- Challenge: Networked robotic vulnerabilities

- Solution: Blockchain-secured robotic operations

4. High Initial Costs

- Challenge: ROI justification for SMEs

- Solution: Robotics-as-a-Service (RaaS) models

E. The Future of Robotic Manufacturing

1. Emerging Technologies

- Quantum computing for robotic process optimization

- Self-healing robotic materials

- Neuromorphic computing for edge AI in robots

2. Sustainable Manufacturing

- Energy-efficient robotic systems

- Closed-loop recycling automation

- Precision resource utilization

3. Hyper-Automation Trends

- Lights-out manufacturing facilities

- Self-configuring production lines

- End-to-end digital twins integration

4. Human-Robot Collaboration

- Augmented reality interfaces

- Brain-computer control systems

- Emotional AI for better teamwork

Conclusion

Robotics is not merely changing manufacturing—it’s redefining the very concept of industrial production. As technologies mature from rigid automation to intelligent, adaptive systems, manufacturers gain unprecedented capabilities to meet evolving market demands. While challenges remain in workforce adaptation and system integration, the trajectory points toward increasingly sophisticated human-robot partnerships that will drive productivity, quality, and innovation to new heights. The factories of tomorrow will be dynamic ecosystems where intelligent machines and skilled workers collaborate to create the next generation of products.

Tags: industrial robotics, manufacturing automation, smart factories, cobots, Industry 4.0, robotic arms, production technology, factory automation, AI manufacturing, future of work

Category: Technology & Industrial Innovation